Birmingham, Alabama, venue for the 67th IEEE-IAS/PCA Cement Conference in May, earned the title of “the Magic City” thanks to its rapid transformation during America’s golden age of industrialisation in the late 19th and early 20th centuries. A fitting location, perhaps, at a time when the 21st century cement industry must perform similar feats of alchemy to achieve decarbonisation of the sector.

The prevailing mood among the nearly 1200 attendees was for the most part optimistic. While uncertainty concerning the Trump administration’s much-vaunted tariffs on foreign imports cast a pall, not least in its implications for the United States’ dependency upon cement imports as a buffer for demand and production fluctuations, it is being received with a stoicism in keeping with the conference’s theme of ‘Sustainable Strength Through Innovation’.

Resilient thinking

Keynote addresses and economic briefings provided delegates with a broad framing of both the challenges and trajectories shaping the industry. Professor David Simchi-Levi of MIT delivered a stand-out presentation on supply chain resilience, offering a rigorous, data-driven framework to assess and prepare for future disruptions. Rather than attempting to predict specific risks, Prof Simchi-Levi argued for structural readiness, advocating a focus on two critical metrics: ‘time to recover’ (TTR) and ‘time to survive’ (TTS). These indicators measure the time required to restore operations after a disruption and the maximum duration the supply chain can withstand without major losses.

Using case studies from the automotive sector and fast-moving consumer goods, he illustrated how small-tier suppliers – often overlooked – can become critical points of vulnerability. Applying this thinking to the cement sector, he urged companies to prioritise transparency and proactive mitigation. He also addressed the limitations of traditional probabilistic risk models, suggesting that companies should engage in scenario stress testing, build digital twins of their supply chains and adopt more agile sourcing strategies.

Representing MIT’s Concrete Sustainability Hub, Dr Liz Moore spoke about how carbon capture utilisation and storage (CCUS) would be critical for decarbonising hard-to-abate sectors such as cement. Her team’s work integrates systems-level thinking with real-world infrastructure modelling to help decision-makers evaluate CCUS deployment across regional and economic contexts.

Dr Moore highlighted how emissions intrinsic to cement production require solutions that go beyond process tweaks, involving shared infrastructure and logistical planning to connect emitters with storage or utilisation sites. She advocated for scenario-based tools that weigh policy, cost and technology maturity when assessing CCUS strategies. She described the project as aiming to “enable widespread adoption” through a design framework that supports resilience and policy alignment.

Keynote speakers included experts from leading cement companies and environmental organisations, who shared insights on carbon capture and storage (CCS) technologies, alternative fuels, and sustainable practices.

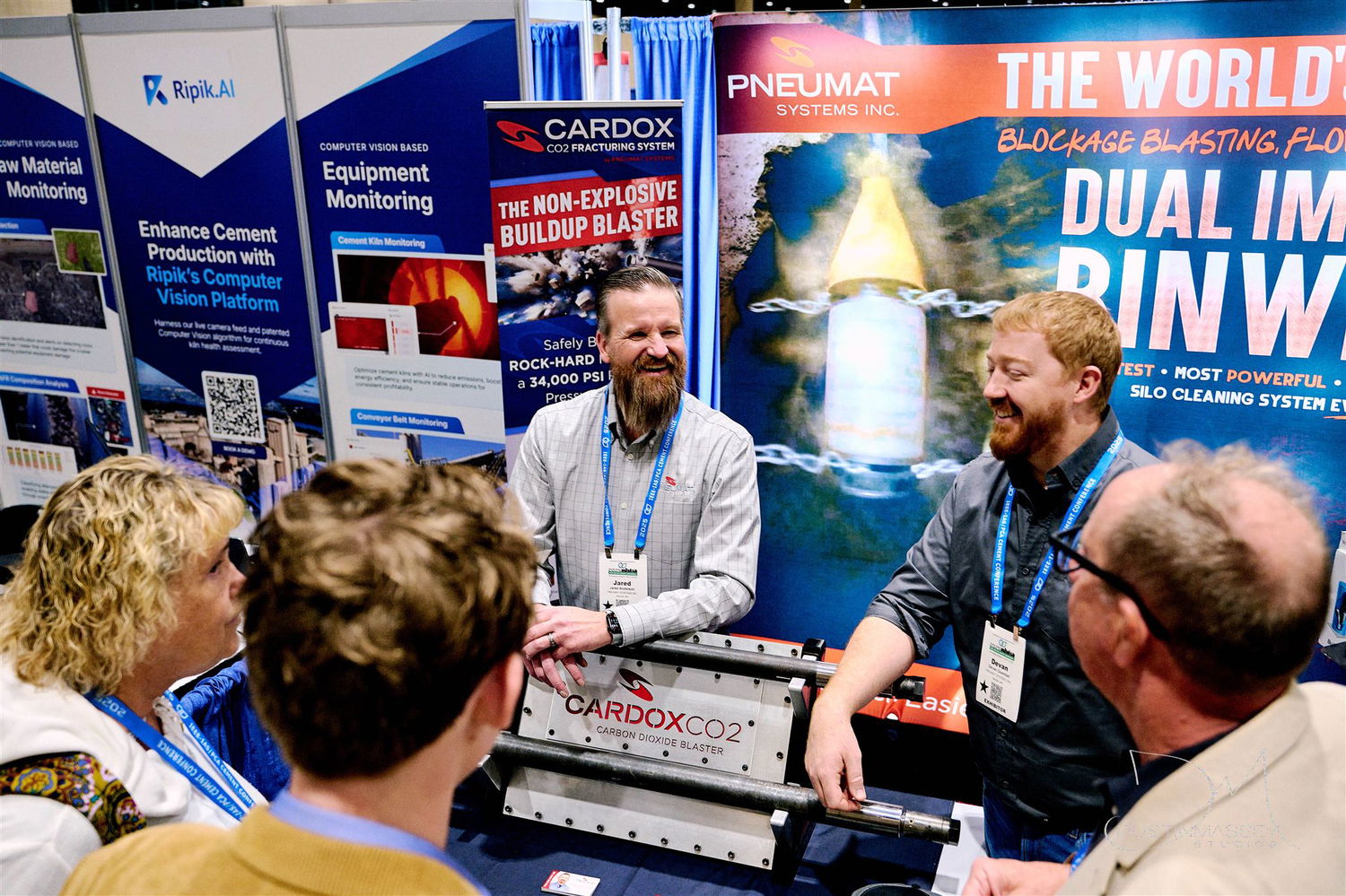

The event featured networking opportunities, panel discussions, and a showcase of cutting-edge products and services from exhibitors.

State of the nation

The issue of imports was the focus of a data-rich analysis by Portland Cement Association (PCA) market intelligence manager, Kaitlin Beer, who traced the evolution of US cement imports and identified regional vulnerabilities should proposed tariffs on foreign cement proceed. With import volumes in some districts exceeding 50 per cent, Ms Beer identified the northeast of the country as being particularly exposed.

Her colleague, PCA economist, Trevor Storck, delivered the association’s spring cement consumption forecast data, cautioning that risks remained high due to interest rate volatility and housing sector drag. “Spending is rising, but we are not seeing a proportional increase in cement use,” he observed, citing rising costs, the use of alternative materials and funding inefficiencies as key contributors. His analysis showed that while infrastructure investment is up, the unit consumption of cement per dollar spent is declining, largely due to rising costs and increased use of alternative materials. He pointed to a longer-term shift in the relationship between funding and consumption that would demand new efficiencies from producers. Both analysts urged the US sector to focus on adapting to their regional markets through responsive capacity planning and better coordination with policymakers to navigate the uncertainty.

Grinding and burning

The top technical paper at this year’s conference was “Optimization of Vertical Roller Mill Systems Using Artificial Intelligence”, which was presented by Dr Caroline Woywadt of Gebr Pfeiffer. Developed with engineers Alexander Peters and Tobias Bäumer, the paper introduced an AI-based system trained on extensive operational data from real-world vertical roller mills.

Unlike static rule-based algorithms, the AI continuously learns and adapts to changing process variables, including feed composition, moisture content and throughput targets.

Deployed at multiple cement plants, the solution showed up to 17 per cent energy savings and 10 per cent increased output without compromising product fineness. Dr Woywadt emphasised that the system is designed to support, not replace, human operators, enabling more consistent optimisation while preserving operational safety and oversight. The AI’s modular structure also allows for phased implementation, making it particularly attractive for brownfield upgrades seeking energy efficiency without major capex.

The runner-up award went to “Following NH3 Combustion from the Kiln to the Calciner”, presented by Dr Tahir Abbas of Cinar. The paper explored ammonia as a carbon-free fuel, using CFD simulations calibrated with full-scale plant data to evaluate NH3 and NH3/H2 blend behaviour under different thermal and flow conditions. Dr Abbas detailed how ammonia can significantly reduce NOx when injected into calciners, cutting kiln-generated emissions by up to 45 per cent.

However, the work also cautioned that under lower-temperature scenarios, ammonia slip becomes a risk, necessitating precise injection geometry and burner configuration. The paper’s detailed combustion maps and simulation outputs offer a practical blueprint for integrating ammonia into cement kilns without sacrificing emissions compliance or combustion stability.

Third place was awarded to “Contributing to Decarbonizing the Cement Industry Thanks to Innovative Combustion Methods”, presented by Fouad Said of Fives. This comprehensive strategy encompasses a suite of technologies including hydrogen-ready burners, oxyfuel capabilities, electric heating elements and advanced calciner controls.

Mr Said presented operational data from pilot and industrial trials showing hydrogen co-firing at 50 per cent by volume, resulting in reduced CO2 intensity and improved flame shaping.

He emphasised that achieving decarbonisation requires system-level flexibility – enabling dynamic fuel switching, enhanced process control and integration with carbon capture-ready configurations. The paper argued for transitioning from discrete retrofits to holistic, modular solutions tailored to plant-specific conditions.

Motors and more

Among other notable papers, Brent McManis and Maicon Martins Joaquim of WEG contributed a paper on ultra-high-efficiency motors. Comparing IE5- and emerging IE6-class motors, showing they discussed their advantages in partial-load and variable-speed settings. The paper noted that replacing a single 100hp motor could reduce emissions by up to 14.5tpa of CO2. Moreover, most IE5+ motors are retrofit-friendly, especially when paired with variable-frequency drives.

Meanwhile, Shannon Timmons of the Canada-based International CCS Knowledge Centre presented “Flue Gas Characterization in the Cement Industry”, co-authored with Patit Pradoo and Laura Westover. The paper compared three design strategies for CCUS projects and found that detailed pre-design testing can reduce the levelised cost of capture by 25 per cent. Ms Timmons emphasised that fuel shifts, contamination, and operational variability demand tailored design, and that up-front investment in flue gas analysis is critical to long-term CCUS success.

Further notable contributions included:

• Paul Edwards of Compressed Air Consultants demonstrated how adaptive compressor sequencing and virtual centralisation can yield up to 30 per cent energy savings in compressed air systems.

• Federico Mercado of GEA Group discussed modular carbon capture systems using waste heat recovery (WHR) integration. The paper proposed scalable amine-based CCUS retrofits capable of operating thermo-neutrally with up to 30 per cent thermal self-sufficiency. The stepwise design approach emphasised flexibility and risk reduction, making it possible to tailor capture capacity to evolving regulatory conditions and financial constraints.

• Neil Wardrop of Leilac introduced hybrid electric calcination as a demand-response tool that could enable grid stabilisation while reducing fossil fuel dependency.

• Daniel Gmeinwieser of RENK showcased a new VRM gearbox design that eliminates jacking oil systems and cuts 20kW of parasitic load, supporting fast commissioning and low maintenance.

• Joseph Spivey presented on a VR-based alternative to the US Environmental Protection Agency’s (EPA) Method 9 opacity certification for emissions, which previously required regular in-person field training (or “smoke school” as it is known) to be deemed competent to visually classify smoke density. EPA-validated, the software is said to offer high compliance accuracy and year-round training access for remote operators.

• Kevin Desjardins of Keith Manufacturing presented findings on walking floor bin systems for alternative fuels. This study provided useful engineering detail on how bin geometry and material flow characteristics affect fuel feed stability.

Conclusion

The 67th IEEE-IAS/PCA Cement Conference illustrated a sector pragmatically adapting to a volatile policy and economic landscape. Casual discussions and presentations alike signalled a shift from incremental improvements to systemic adaptation, with digital optimisation, modular design and flexible fuel strategies taking centre stage.

Whether or not the innovations showcased can be effectively implemented at scale will of course only be revealed with time. Delegates were invited to convene again at next year’s 2026 event, which will take place in Fort Lauderdale, Florida. Please see: https://www.cementconference.org