An AI co-pilot for plant optimisation

Cement producers are under growing pressure to reduce emissions and cut fuel costs - all while managing volatile alternative fuel supply, expanding product mixes, and increasing process complexity. Traditional control systems alone are no longer enough.

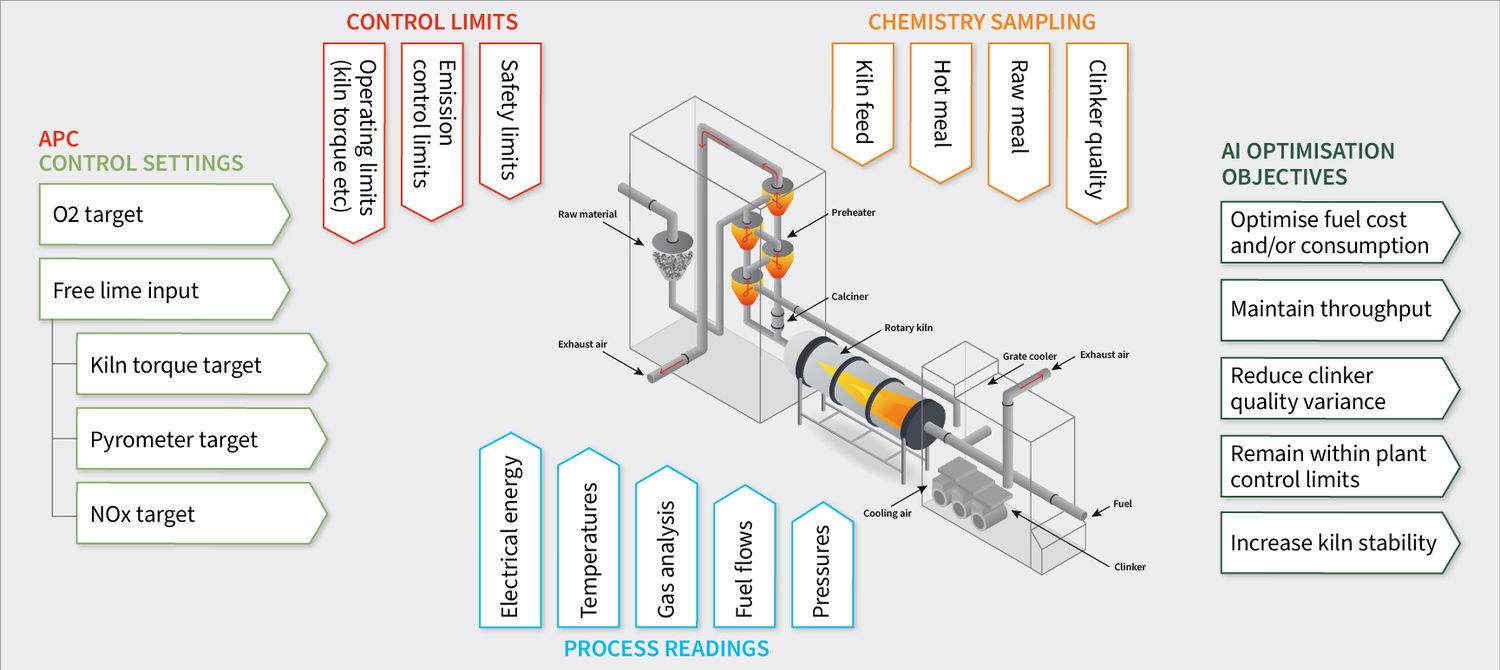

Carbon Re acts as an AI co-pilot for process engineers. Using machine learning models trained on live plant data, it continuously predicts key process parameters and recommends proactive control changes. These soft sensors and recommender systems operate in real time, adjusting to plant variability and helping maintain peak performance.

Burn smarter, not harder

Carbon Re enhances kiln stability, reduces clinker quality variation, and enables higher TSR without compromising operational constraints.

It is cloud-based and cybersecure, with models that self-learn and self-tune over time. This means no re-calibration is needed, and performance is maintained even as operating conditions evolve. By freeing up engineers from constant manual tuning, Carbon Re allows production teams to focus on strategic improvements, not firefighting.

Real results

Cement manufacturers using Carbon Re’s AI process control are seeing:

- 5.4% reduction in specific heat consumption

- 3.8% increase in TSR (at a plant already operating at 86%)

- 33% reduction in C3S variability, improving clinker quality and consistency

These benefits lead to lower fuel costs, reduced carbon emissions, and more consistent quality — making operations both more efficient and resilient. On average, plants are saving $1.50 per tonne of clinker produced.

Easy to deploy, fast to deliver value

Deployment is straightforward: there’s no need for new hardware, and integration can be completed in weeks. Once active, the system begins identifying opportunities and recommending improvements almost immediately - delivering payback typically within three to six months.

For process engineers, it also frees up valuable time by reducing the need for manual adjustments and shift-to-shift troubleshooting.

“Carbon Re exceeded our expectations. We didn’t believe it was possible for them to deliver the live connection and dashboard in 8 weeks. Not only did they deliver on time, the real-time insight we gained into our operations was incredibly valuable from day one”

Jirí Strapina, Mokra Plant Director

AI today - and for the future

AI process control is purpose-built for the complexity of modern cement production, empowering plants to make faster, smarter decisions every day. Carbon Re’s technology is helping the industry reduce both costs and emissions - and as the system learns and adapts over time, its impact continues to grow.

Through strategic partnerships with industry leaders such as FLSmidth and ABB, we’re expanding access to AI process control across the industry, enabling more producers to hit fuel efficiency and emissions targets without compromising stability or performance.

Looking ahead, AI will also be critical to the success of Carbon Capture and Storage (CCS). By improving process stability and controlling flue gas composition, AI makes CCS both technically and economically more viable. A key step towards a net zero future for cement.

For producers, adopting AI today isn’t just a digital enhancement - it’s a strategic investment in resilience, performance, and long-term competitiveness in an increasingly demanding world.

Learn how to decarbonise profitably at: carbonre.com