The cement industry sits at the intersection of two global challenges: building the infrastructure needed to support a greener planet, while at the same time being a major contributor to global CO2 emissions. We are both part of the problem and an essential part of the solution.

Alternative fuels remain a key component of a greener cement industry – yet most cement plants continue operating with limited alternative fuel adoption due to technical constraints, fuel quality concerns and a lack of consistent fuel supply. The good news is that solutions exist to counter these concerns and are already at work in real commercial operations today.

“Cultural and operational dynamics are often just as influential on the road to Net Zero as access to technology”

How ‘circles of influence’ drive or limit fuel substitution

Several factors influence the success of a fuel substitution project. These range from internal considerations – like technical capacity and innovation culture – to external factors – such as local infrastructure and fuel markets, broader policy, and regulatory pressures. Understanding these circles of influence helps us identify where to start and how to help a plant map out its decarbonization journey.

For instance, a plant with a strong in-house technical team and an openness to innovation will approach fuel substitution very differently than a more conservative operation that relies heavily on third-party support. These cultural and operational dynamics are often just as influential on the road to Net Zero as access to technology.

On the infrastructure side, regions with established preprocessing systems for alternative fuels, like Denmark, have a very different starting point compared to places like parts of India or even the U.S., where that infrastructure may be less developed. These conditions affect not just the feasibility but also the speed and scale of fuel substitution.

There is no silver bullet... Success depends on matching solutions to each plant's unique circles of influence

Alternative Fuel Technologies

Alternative fuel technologies have come a long way over recent decades, enabling far greater substitution rates – even where fuel supply is inconsistent. Here, we’ll outline three proven technologies: two widely used and one recent innovation.

ILC Low NOx Calciner

The ILC Low NOx Calciner is well suited for firing a high percentage of waste fuel, enabling cement producers to achieve 100% fuel substitution in the calciner. It offers three key features that make it ideal for high TSRs:

- It can handle particle sizes up to 100x100 mm

- It provides high oxygen availability in the lower zone

- Combustion times range from 20 to 60 seconds, depending on particle size, enabling complete burnout of even coarse materials.

It’s worth noting that smaller, more uniform particles burn faster and more efficiently, but the calciner can burn 50 mm tyre chips and even larger particle sizes. The takeaway here is that fuel preparation directly impacts combustion performance – so the design of the fuel feeding and combustion systems should be tailored to what is available to the individual plant. A design that is tailored to the plant’s circles of influence.

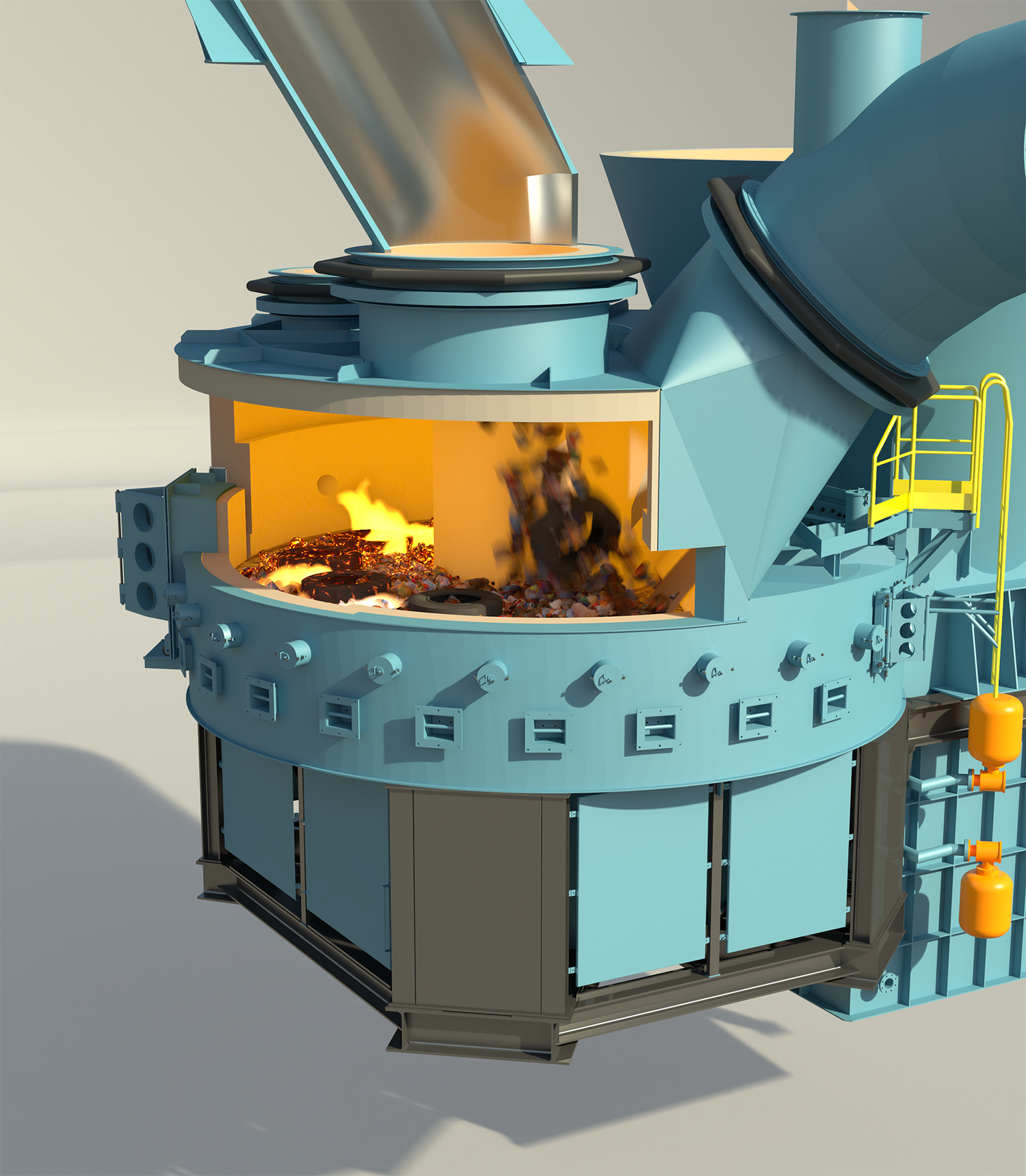

HOTDISC® Reactor

If you’re looking for maximum fuel flexibility with minimal preprocessing, the HOTDISC® Reactor is a powerful solution. Many plants use it to achieve 80 – 90% fuel substitution. It’s particularly effective for low-grade fuels like sludge, shredded waste, and even whole truck tyres.

The HOTDISC® is essentially a rotating horizontal furnace that allows a wide variety of solid fuels to be used without shredding, even fuels with a moisture content above 50%. This lowers preprocessing costs and makes fuel sourcing easier, especially in regions where preprocessing infrastructure is underdeveloped. It also decouples your plant from any single fuel supplier or fuel quality specification.

With variable speed drives, retention times can range from 3 to 45 minutes, which ensures complete combustion and helps avoid issues like cyclone blockages.

HOTDISC® variants, such as the HMT version introduced in 2021, ensure the HOTDISC® can be matched to your plant’s requirements and footprint.

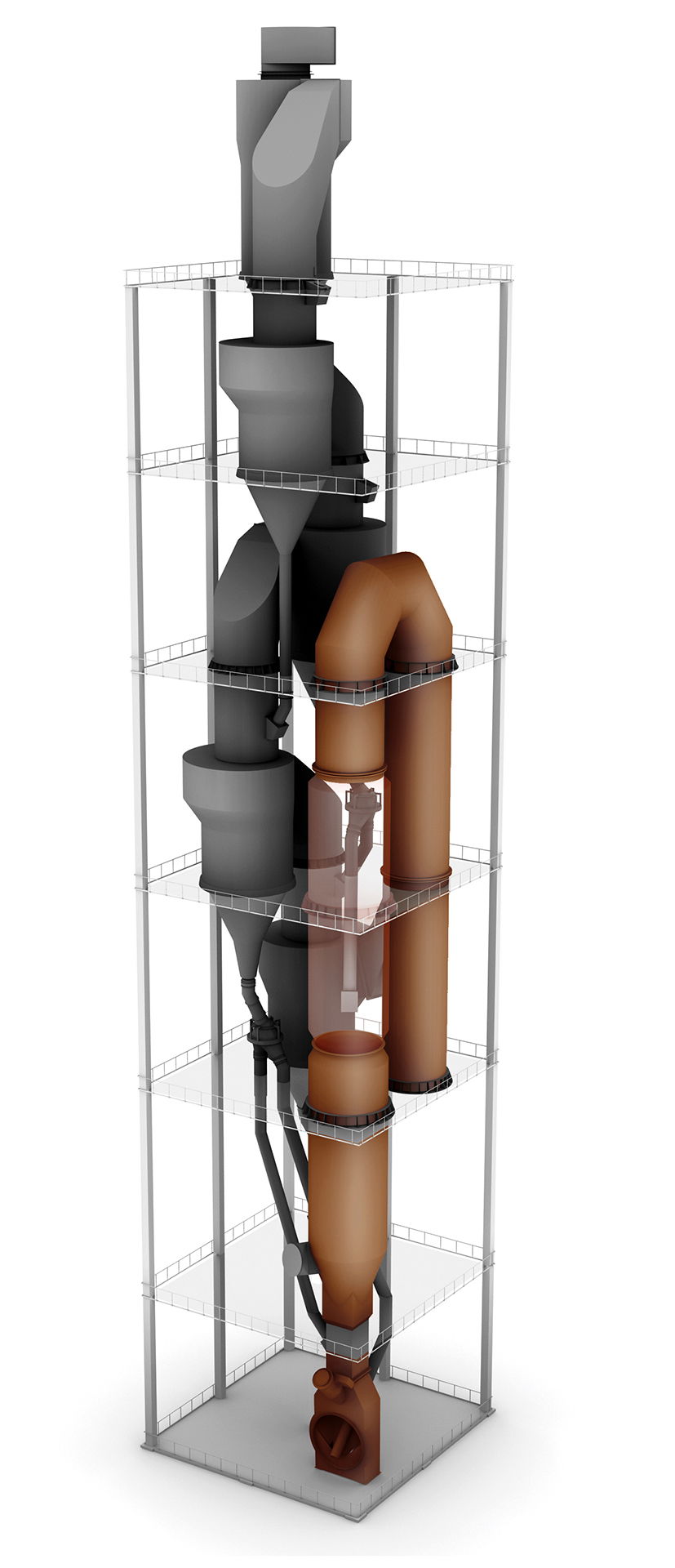

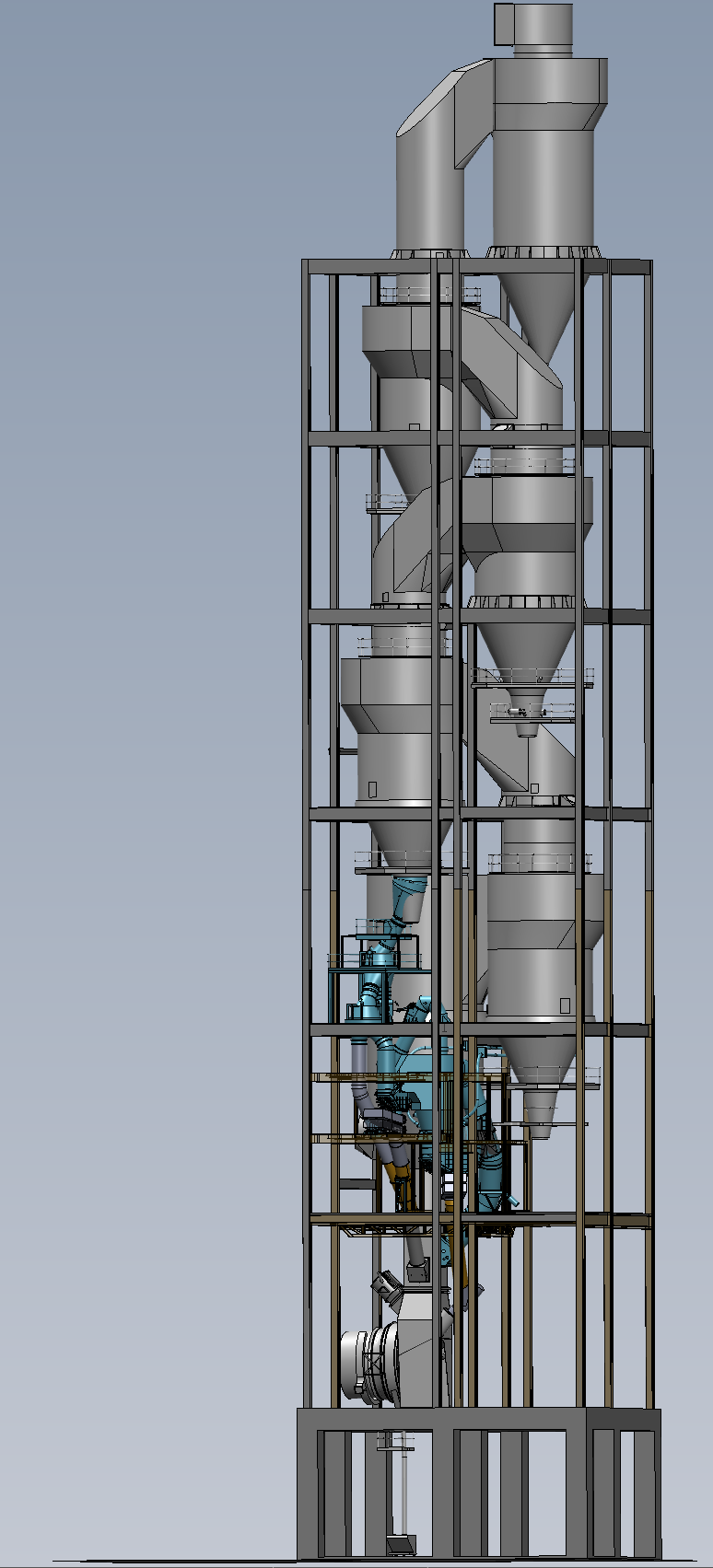

FUELFLEX® Pyrolyzer

The FUELFLEX® Pyrolyzer is a new innovation from FLSmidth Cement that allows plants to substitute fossil fuels with RDF or biomass-derived fuels without requiring large-scale calciner modifications. It is simply bolted on to the calciner and is, again, tailored to the existing operation.

The pyrolyzer heats material in the absence of oxygen, breaking it down into combustible gases and solids. The result is a highly reactive, energy-rich gas stream that supports high-efficiency combustion.

The benefits go beyond fuel flexibility. In one real-world case, we saw NOx emissions reduced from 474 to 358 mg/Nm³, with complete elimination of ammonia dosing systems – delivering both environmental and cost benefits. This solution is especially relevant in markets like India or Latin America, where plants face physical space constraints or regulatory limits on ammonia usage.

With ROI typically achieved in 1 – 3 years, depending on local conditions, FUELFLEX® offers an economic, sustainable solution that can be easily retrofitted to existing processes.

The green transition will be a continuous journey. What matters is to start now, learn quickly, and build incrementally.

Integrated automation

Importantly, these fuel systems don’t compromise quality or throughput. Process control tools like ECS/ProcessExpert® smooth the transition between fuels with ease and ensure consistently stable kiln performance. Advanced dosing systems such as the Pfister® TRW-S/D and FEEDflex deliver precise fuel flow control and enable dramatic reductions in fossil fuel use without removing the flexibility required at start-up or when alternative fuel supplies are low. Integrated gas analysis systems (KilnLoq®, GASLoq®) continuously monitor emissions, helping you optimise combustion and ensure you’re meeting regulatory requirements.

Even if you start small – start now

There is no silver bullet for decarbonization. Success depends on matching solutions to each plant's unique circles of influence – their internal capabilities, regional fuel markets, regulatory frameworks, etc. It's about combining the right technologies for your specific context and acknowledging that the green transition will be a continuous journey. What matters is to start now, learn quickly, and build incrementally. Every plant, regardless of size or location, can take meaningful steps today.