Grinding specialists Loesche held a successful Loesche Symposium on 25-26 September 2014 at the Hyatt Regency Düsseldorf, Germany. The two days offered a platform to introduce the latest advances in the company’s grinding technology as well as share experiences with mills already installed at various cement producers worldwide.

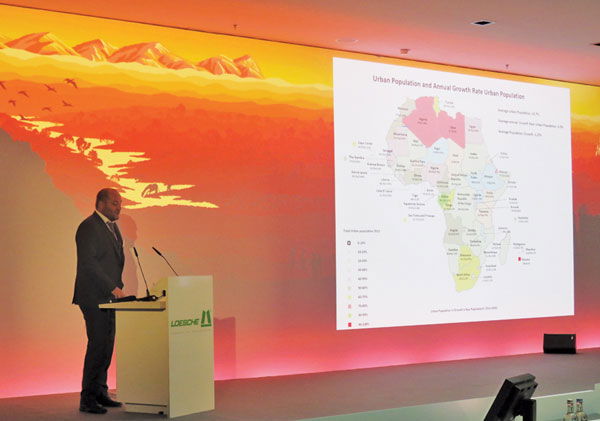

Dr Daniel Camarasa gave a valuable insight into the development of Africa’s economy

and cement markets, reflecting Loesche’s international reach

After a warm welcome by Loesche’s CEO, Dr Thomas Loesche, Dr Daniel Strohmeyer, director of Process Technology, updated some 340 delegates the latest developments in Loesche grinding technology. Product development at the company is primarily driven by product requirements, environmental consideration and resource limits of cement production. He explained the trends towards larger mill sizes such as Loesche’s LM70.4+4 and 70.5 range and the need for improved performance, which is delivered by its new LDC classifier.

Dr Thomas Loesche welcomed over 340

delegates to the 2014 Loesche Symposium

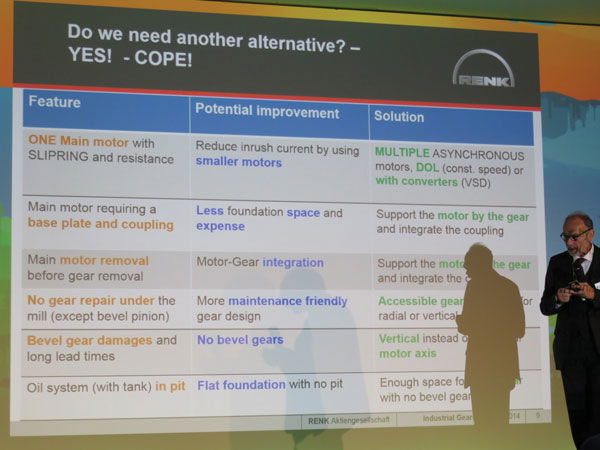

Peter Boiger of Renk followed on, focussing on one specific feature of Loesche VRMs, the COPE (COmpact Planetary Electric) drive, and brought 32 years of experience in the field to bear as he highlighted the equipment’s higher availability and lower total cost of ownership (TCO).

Olivier Thomas and Pierre Wlodarzyk of Loesche introduced the company’s new ‘Operation and Maintenance’ business line, which sees the equipment supplier provide a multi-level maintenance and repair service through the entire lifecycle of a cement producer’s installed grinding mills, ensuring smooth operation and maximum uptime.

Industry endorsement

Loesche’s grinding technology also enjoyed support from the industry as reflected by a series of presentations from leading cement producers.

Alexander Flacher, who heads Holcim Group Support, took visitors through the history of VRMs used in clinker grinding by the Swiss cement producer. The company operates at present 33 VRMs, of which 17 were supplied by Loesche. Meanwhile Dr Dirk Spenner, MD of Spenner Zement, discussed the operating experience of the first VRM for GBFS grinding at the Germany cement plant.

In his presentation, Peter Boiger of Renk

explains the benefits of the COPE drives

installed in Loesche’s vertical roller mills

Moving to the Middle East, Southern Province Cement Co presented a first in Saudi Arabia as it informed delegates about the new VRMs installed. Radwan Mouakat of National Cement Co, UAE, explained the cost savings obtained due to the company’s fuel conversion project from HFO to pulverised coal.

A view from India was offered by M Srinivasan of Madras Cement and V S Narang of My Home Industries advised the audience on their operating experiences with Loesche mills.

Sustainability

Sustainable cement production also featured prominently on the symposium agenda. Prof Horst-Michael Ludwig of Bauhaus Universität Weimar then explained the production of high-quality binders from steelmaking slags.

Dr Gerald Wimmer of Siemens VAI, Austria, explained the innovative approach for LD (Linz-Donawitz) slag valorisation to reduce clinker factors in the cement-making process. The company’s technology will enable the use of LD slag in the production of cement, effectively reducing the clinker factor and thus bring down specific CO2 emissions, he explained. Moreover, the effective use of LD slag will reduce the slag’s negative impact on the environment as landfill or other disposal options will be no longer required to the same extent, Dr Wimmer added.

ZKG’s Dr Hubert Baier sketched a general view on future alternative fuel trends, effectively introducing a series of papers offered by A TEC specialists. These covered various aspects of alternative fuels, ranging from the company’s new chain mill, presented by Johannes Uttinger, to its integrated solution for NOx reduction, as described by Dr Stefan Kern. Joel Maia shared the first results of A TEC GRECO’s new main burner for 100 per cent alternative fuels. A TEC’s Johannes Müllner and Ernst-Michael Sipple of Holcim highlighted their experiences with the first ‘ReduDust’ installation, while ATEC’s Friedrich Willitsch explained ways to reduce mercury emissions in the cement kiln.

Additional grinding aspects

Further perspectives on VRMs, their potential use in grinding operations and additional applications were provided by a varied range of presentations. Sintek’s Onur Atakay reflected on the change of preferences that sees VRMs take the centre-stage rather than the traditional ball mill.

An exhibition with a selection of associated equipment suppliers accompanied the symposium,

providing additional information to existing and potential customers

Selective communition and dry sorting were the subject of two papers by Loesche’s Andre Baetz, Carsten Gerold and Dr Holger Wulfert as well as Dr Andreas Jungemann and Dr Andreas Schiffer of Cala.

Matthias Mersmann of aixergee highlighted process optimisation in the cement industry.

Finally, the symposium was brought to a close by Dr Thomas Loesche who reflected on the presentations given.