The 9th PetroCem was held at the Astoria Hotel, St Petersburg between 24-26 April 2016. Some 500 delegates listened to a comprehensive programme that included leading cement producers and analysts as well as equipment suppliers, while a 50-stand exhibition provided expert knowledge and support. By ICR Research, UK.

PetroCem 2016 opened with a distinguished line of speakers, including Igor Shikalov, Ilya Chigir,

Mikhail Skorokhod and Ivan Borisov

Mila German, conference organiser and editor of Journal Cement, opened the proceedings and remarked on how the conference had grown since its first event back in 2000 when there were just 170 guests attending.

Since then the Russian cement industry has seen a fantastic rise, but today it is facing more turbulent times. While the domestic cement industry is holding back on capacity expansions, significant projects are currently being undertaken, transforming existing capacity into modern dry-process works and reducing production costs.

Taking place in St Petersburg, PetroCem delegates were welcomed by Dr Ivan N Borisov of the Belgorod State University of Technologies. He explained that the city was one of the most stable centres of activity for the construction sector.

Russian market

Ilya A Chigir of the Ministry of Industry and Trade spoke about the development of construction materials in Russia up to 2020. He explained the need to attract private investment. The cycle of investment in Russia’s cement sector led to a cement capacity of 108Mta in 2015, but half of the production is still out of date and there has been a fall in demand for products. Mr Chigir called for improved competition. Furthermore, in a drive to eliminate counterfeit cement on the market, new standards are being introduced, along with other regulatory initiatives and the need to raise material recycling.

Mikhail Skorokhod, president of the Eurocement Group, stressed the need for a single Eurasian market where goods can move tax-free. The Eurasian Economic Community (EAEC) has seen its production fall 10 per cent YoY to 77Mt in 2015. For the current year, a further eight per cent drop to 71Mt is expected. Capacity utilisation is currently at 52 per cent with EAEC production capacity at 139Mta.

European challenges and opportunities

Koen Coppenholle of Cembureau acknowledged that many issues faced by Russia are also present in Europe as he spoke of the regulatory challenges and opportunities for the European cement sector. Europe has seen a 40 per cent fall in cement output since 2008 and the market is plagued by a lack of competitiveness.

However, positive steps are being taken. Russian standards have moved closer to those in the EU and trade is increasing, bringing with it a need for increased competitiveness.

In terms of sustainability, concepts such as the circular economy and a lifecycle approach to materials are part of innovative moves that help improve resource efficiency and mitigate climate change. Mr Coppenholle stressed the importance of recognising that concrete is a sustainable product at the end of the supply chain, one that is not only durable, but also recyclable.

Finally, Cembureau reported that the cement industry presently has a fuel substitution rate of 38 per cent with a target of 60 per cent to be reached by 2050.

Global trends

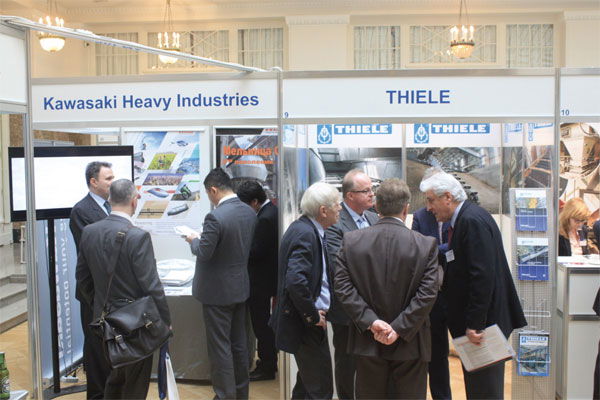

A 50-stand exhibition complemented the conference proceedings

Yassine Touahri of Exane BNP Paribas shared his vision of a new era in the global cement markets. He noted the three per cent fall in global cement demand in 2015. There was a recovery in North America and India, while western Europe saw a decline along with an eight per cent drop in Russia. Demand in Brazil fell by 10 per cent and by five per cent in China.

Although oil-importing countries are expected to see benefits in 2016, the majority of emerging economies are forecast to witness declines in construction growth and cement consumption. While the US can anticipate an increase in utilisation rates, the recovery in Europe will be slow.

Moreover, many countries that export to China can expect to see cement volumes drop by a further 10 per cent as cement consumption in the Asian giant is stabilising at around 4bnt after a period of strong growth. To maintain utilisation rates, Chinese producers are expected to export some of their cement, but uncertainty remains in terms of volume sizes, particularly as most of China’s capacity is located inland.

While coal and petcoke prices are trading low at around US$60/t, overall cost inflation will remain high in many emerging markets. Cement prices are also expected to fall in South Africa, Brazil, Indonesia and Turkey.

Mr Touahri moved on to discuss why the cement sector is seeing large multinational mergers between cement producers, such as Lafarge and Holcim, and HeidelbergCement and Italcementi. He attributes the mergers to a series of factors, including the disappointing returns for shareholders and low cement prices as well as an opportunity to restore profit margins through synergies. For LafargeHolcim cash flow generation is the main target now. Investment is expected to drop by 30 per cent in 2016 and the company will sell over US$3.5bn of its assets.

HeidelbergCement and Italcementi are following suit this year. The merger will help HeidelbergCement to increase its presence around the Mediterranean Rim and move into Asian markets such as Thailand, but the new company will have no capacity in Latin America.

Further industry consolidation could occur in Russia and the CIS countries. In Italy there is the possibility of asset swaps and consolidation of family businesses while in China some producers are also expected to amalgamate. In Latin America Brazil may also see some collaborations and Cemex is not ruling out a future merger. North American producers could also find this to be an answer to expanding production as building new capacity in the region is expensive and time-consuming.

Mr Touahri then turned to the Russian cement market, in which cement producers face a challenging future with capacity utilisation set to drop below 55 per cent in 2016. Moreover, in the fragmented market, all producers are expected to fight hard to maintain their market share. Cement prices have fallen in real terms due to the depreciation of the ruble in 2012. However, the cement sector’s falling utilisation rates and fragmentation means that it is unlikely to raise its cement prices to counteract the effects of the currency depreciation.

Further presentations examined technology in the cement industry with speakers from Verein Deutscher Zementwerke (VDZ), Freight One and Sberbank before the first lunch interval. Martin Schneider of VDZ highlighted the improvements made in Germany in producing composite slag cements, reducing the clinker factor and CO2 emissions and he pointed to the global clinker factor average being at about 75 per cent which is dependent on the availability of raw materials such as slag and fly ash. The cement of the future will still be Portland cement-based though, he said, and manufacturing it more efficiently and with more additives will be the challenge.

Mikhailovsky Palace provided a stunning setting

These views were complemented by presentations by other speakers including CMPro on supply and demand forecasts in Russia, KHD’s 6000tpd new dry kiln line for OAO Novoroscement, HeidelbergCement Russia’s gas flow changes at Tula Cement as well as presentations from FLSmidth and a market review on the Belarus and Azerbaijan cement industry.

Russia and the environment

On the second day highlights included AI Kalachev of ProfCement sharing his views on the issues related to the use of thermal power-generated fly ash in Russia’s cement industry and SP Sikov of CEMISCON’s outline of mandatory cement certification in the country. Mr Sikov explained how Russia’s cement producers’ association, Soyuzcement, would implement cement certification in Russia through certification bodies. Inspection of cement facilities was made obligatory in September 2015 to retain the quality of Russian cement, ensure the appropriate equipment is being employed to control relevant parameters and to protect the industry against counterfeit cement. While there are more than 100 cement-producing facilities, many of them do not have test labs. However, the qualified test centres of CEMISCON, BelGTASM-certification, Mosstroandcertification and JSC Research Centre of Construction could carry out tests in accordance with GOST R 56836-2016 for compliance evaluation.

OV Dvinyanina, NII Atmosphere, also spoke on best available technologies (BAT) for the control of contaminant emissions in Russia. A new federal law (No 219-F3) was issued in July 2014 for pollutant emissions to the atmosphere. By January 2019, to obtain a comprehensive environment permit, emissions will be calculated taking into consideration the process parameters given in the BAT reference document for cement production and the technical standards for emissions will be identified for every plant.

K Gridnev of SICK AG followed up on the environmental monitoring and implementation of the federal law 219 by explaining that by 2022 the transition to integrated environmental permits with a valuation on the basis of BAT is targeted. In the long-term, Russia’s federal government aims to harmonise domestic legislation with its European counterpart.

The conference was concluded with an FLSmidth-sponsored gala dinner at the stately Mikhailovsky Palace, one of the finest works of early 19th-century architecture in St Petersburg.

Article first published in International Cement Review, July 2016.