Germany-based grinding specialist Loesche held its 2017 Symposium under the banner of “Evolving the future” on 6-7 September at the Maritim Hotel in Düsseldorf, Germany. Around 500 delegates from cement companies and suppliers attended the event to take stock of the latest developments in grinding and help Loesche celebrate its 111th anniversary.

Some 500 delegates gathered to hear Loesche's latest advances in grinding technology

Following a warm welcome to the Loesche Symposium 2017 by Dr Thomas Loesche, owner of Loesche GmbH, the company’s Managing Director, Ruediger Zerbe, reflected on Loesche’s 111 years of “Evolving the future”.

Facing a challenging market

The current and future challenges of the global cement industry were put into focus by Jacques Glemarc, senior vice-president of LafargeHolcim, as he explained the market needs for the right product and sustainable production with the industry’s requirement to produce cement that has a good return for shareholders with a lower environmental impact.

A background to the development of the global cement sector was supplied by Dr Joerg Kraemer, chief economist of Commerzbank, who presented an outlook on the global economy and the financial markets. Asif Boda of HSBC Bank London provided the HSBC perspective on the outlook for global cement markets.

Sinoma’s “Innovative Cooperation for Triple Prosperity” by Shen Jun, chairman of Sinoma International Engineering Co, Nanjing, China, highlighted the close cooperation between one of China’s key equipment suppliers and the conference hosts.

Dr Regina Krammer of Loesche’s technical training and documentation department introduced delegates to the “Barcamp”, the company’s new form of information transfer.

There was also time to showcase flagship projects

such as the new 36,000tpd Beni Suef works, Egypt.

Via main contractor Sinoma CDI, Loesche is supplying 18 mills

to grind raw materials, cement and coal at the six-line plant

High-quality cement production

Production of high-quality cements featured Prof Dr Horst-Michael Ludwig Bauhaus-Universitaet Weimar, who gave an overview of products and trends in the worldwide cement market. Dr Daniel Strohmeyer of Loesche Technology provided more detail on how to produce high-quality cement with Loesche VRMs and the factors that need to be taken into account to achieve the best results.

High production rates

Following the lunch break a series of presentations were given to help producers achieve high production rates. Loesche’s Dr Mathis Reichert provided more information on how to master the market demand for ever-larger grinding capacities.

Dr Arif Bashir, director of technical and operations at DG Khan Cement, supplied his experience with Loesche’s COPE drive in his presentation “Most modern grinding plants with world largest COPE drive to commence operation in December 2017 – DG Khan Cement, Pakistan”.

Dr Thomas Loesche, owner of Loesche GmbH,

addresses guests during the Gala dinner.

High-value grinding in practice

In the fourth session of the day, Loesche examined the ways in which customers can get more value out of cement grinding. Major capacity expansions in Bangladesh and the UAE were highlighted by Loesche’s Thomas Fahrland. His colleague Piere Wlodarzyk provided a business model for a fast market entry, while Omar Bekri, general director of Cemos Ciment SA, supplied an insight into taking the need for a compact grinding plant from an idea to execution.

Operation and maintenance

With more cement companies keen to extract the most from their grinding plants, Loesche has further developed its operation and maintenance (O&M) services. Olivier Thomas, managing director of Primetec, supplied information about O&M services in delivering profitable and reliable production with an edge. Loesche’s Dr Dorival Tecco provided a both informative and entertaining insight on the new benchmark for modern grinding parts. His colleague, Ralph Viebrock, who heads up the company’s Customer Services Department, looked into the future as he explored the next service level, Digital Interaction.

Maximising AF utilisation

In light of reducing carbon emissions and lowering fuel costs, cement plants are increasingly turning to the use of alternative fuels (AFs). Matthias Mersmann, managing director of aixergee, guided delegates step-by-step towards achieving higher substitution rates. Dr Stefan Kern of A TEC informed the audience about new ways of processing AFs. A view on AF use in action was provided by H Salzlechner as he showcased the experiences of the Wietersdorf cement plant in the use of such fuels.

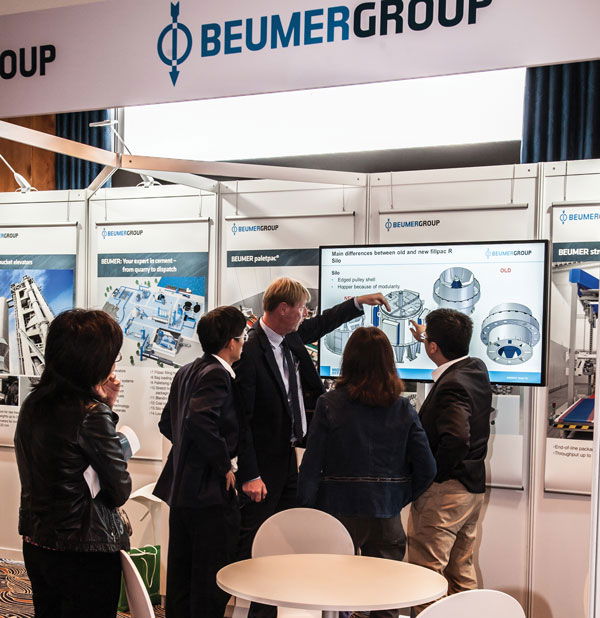

Guests could also discuss their requirements with

various equipment suppliers at the accompanying exhibition

New ways of interaction

The conference also introduced Loesche’s Barcamp initiative. The Barcamp is the company’s new way of interacting with its customers. The method enables all Barcamp participates to post topics to which fellow participants can express interest in attending the virtual conference. This way of setting a meeting agenda ensures that topics are highly relevant for the participants as they sign up for those themes, which are often grounded in practical experience, that are directly relevant to them and tailored to their needs.

In addition to a series of inspiring presentations, delegates also visited the Mannersdorf cement plant in Austria to see Loesche technology in action before the close of the symposium.

This article was first published in International Cement Review in November 2017.