At the end of August 2012, Haver & Boecker’s machinery division hosted the Haver Technology Days at the A2 Forum in Rheda-Wiedenbrück, Germany. The meeting for company employees, representatives as well as customers focussed on providing clear, first-hand information on the company’s latest strategic and technical innovations and also marked the 125th anniversary of Haver & Boecker’s founding.

Now in its jubilee 125th year, Haver & Boecker in still expanding its technology and its ability to serve new markets

The Haver Technology Days conference, held on 27-29 August 2012, was the second time the company has hosted such an event – focussing on direct interaction with potential and long-term customers. Since the first meeting in 2008, the company has taken innovations directly to its clients in the cement, building materials and mineral processing industries, all of which have benefitted from these technological developments.

The main goal of this year’s event was to emphasise that Haver & Boecker wishes to be involved in the development of processes at the early stages of a partnership in order to find improved solutions borne out of collaborative efforts.

Strategy day

Dr Aliko Dangote expressed his vision

for Africa's cement industry development

On day one of the conference, entitled ‘Strategy Day’, managing director and partner Dr Reinhold Festge introduced a host of renowned speakers. The main guest speaker was Dr Aliko Dangote, who travelled from Nigeria to speak especially on the stellar development of Dangote Cement and his dreams for the African cement market.

Other speakers included Dr Martin Wansleben, main director of the German Chamber of Industry and Commerce, who spoke on globalisation as a challenge for mid-sized companies and Prof Dr Unland, Saxony minister of finance and professor at the Technical University of Bergakademie Freiberg, who discussed the shortage of raw materials for the cement industry and ways to curb it.

SpeedFlexx

As a highlight of this year’s gathering, invited guests were also able to witness the official launch of the company’s SpeedFlexx loader, a loading system for open-bed trucks.

The SpeedFlexx, a fully-automatic direct truck-loading system, extends Haver & Boecker's

product range of packing and loading technology

The recent acquisition of Newtec Bag Palletizing has offered Haver & Boecker the opportunity to complete its shipping logistics with the new SpeedFlexx loader which combines direct, just-in-time loading and conventional palletising technology with stocking. High-speed loading of up to 260tph can be achieved and the system’s flexibility allows delivery to stock in the event of no trucks being available. The system utilises conveying and stationary palletising technology for reliable operation. Filled bags are handled with shipping and in-house pallets as well as sheets.

| A date with history |

The latest addition to the Roto-Packer family is the Roto Classic, introduced in 2008 |

|

The first Haver & Boecker conference for company representatives – which took place in September 1960 at the company’s headquarters in Oelde, Germany – was attended by many of its European members. The main purpose of the meeting was to introduce the Haver Roto-Packer, a rotating packaging machine, which had just been added to the company’s product line. The Roto-Packer impressed guests immediately and, from that point on, such representative meetings have been held on a regular basis. These meetings now attract an increasing global reach and include participants from as far afield as South America and Asia. |

The SpeedFlexx loading cycle begins by scanning the truck-bed surface using optical analysis technology to produce a 3D image to check that the truck is ready for loading. Open trucks on two travel lines are loaded with stacks of bags via a feeding rack. Once the first truck is loaded, the SpeedFlexx changes lanes to start filling the second truck. This results in continuous, high-speed loading.

When trucks are unavailable, SpeedFlexx can load pallets with bag stocks. The machine can also operate in reverse and be fed from filled stock.

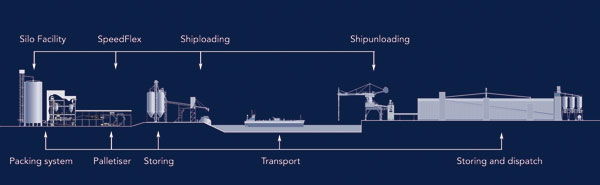

Complete filling solutions

The Haver & Boecker machinery division was founded in 1925, focussing on the design and production of packaging and screening machines. More than 85 years later, the division views itself as a supplier of complete solutions for filling technology. Together with other members of the Haver group, it offers silo stocking, shiploading and unloading, packing, palletising and loading of trucks. The machinery division is able to establish and control an entire electrical and engineering automation installation.

The company’s recent project at the Cementa SA Malmö cement terminal in Sweden demonstrates the new benefits for customers (see ICR July 2012). For this project, Haver & Boecker worked with its subsidiary IBAU Hamburg who was the general contractor. Haver & Boecker supplied the electrical and automation requirements, including a PCS7 process control system with CEMAT technology.

Customers can now work with Haver & Boecker under a single contract during the planning and execution of complex storing, packaging, palletising and loading lines for the cement industry.

Article first published in International Cement Review, October 2012.