With the cement sector now under pressure to improve the efficiency of operations, Industry 4.0 brings new opportunities. The study presented in this article provides a novel data-driven approach to predicting weighing deviations in the loading of bags, pallets or bulk cement into vehicles at a cement plant. Real-world empirical data was used to explore different machine learning classifiers and compare their predictive power to improve dispatch workflow process efficiency. By Júlio Barros, João NC Gonçalves and Paulo Cortez, University of Minho, Portugal, and Francisco Cunha and Cândido Martins, Cachapuz, Portugal.

The introduction of the Industry 4.0 paradigm and the profound digital transformation1,2 are changing the mindset of companies towards integrated supply chain management. Industry 4.0 refers to a new phase in the industrial revolution, ie, the Fourth Industrial Revolution.3 With it, new concepts such as Cyber-Physical Systems (CPS) have emerged, which represent a new generation of integrated computer systems with the physical world.4

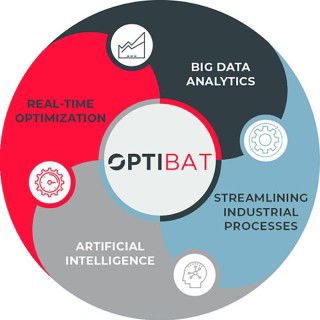

The increasing search for and development of CPS have led to the exponential growth of network-connected devices. The connectivity of these devices generates a considerable amount of data that can be converted into valuable insights through data analysis and integration. This improves the decision-making process, creating value and offering competitive advantages. 5